As the world grapples with a rising population and an ever-larger demand for goods, the need for transportation continues to grow. To best serve society, we need transport that is not just fast, safe, sustainable, and affordable but also profitable – to ensure that it is not a drain on taxpayer funds. Yet, most traditional modes of transportation – road, rail, and airlines – have failed to generate profits consistently. Innovation is needed in the transportation industry, and TransPod is working to meet that challenge. TransPod is developing a transportation system that is faster and more affordable than a plane, comfortable for riders, and fully electric.

People often ask if TransPod can achieve those goals while keeping the system profitable. The answer is a resounding yes. This article will discuss how TransPod’s technology and operating model make it profitable, unlike the current gold standard for high-speed ground transportation: the magnetic levitation (maglev) high-speed rail.

The Current State of Profitability in Transportation

It’s essential to understand the current state of profitability in transportation.

There are four modes of transportation to consider – road, rail, ship, and plane.

Cargo transportation is generally profitable across the board, as demonstrated by the performance of some leading companies in the industry. A.P. Møller – Mærsk, a leader in marine shipping, generated US$17.9 billion in net income in FY2021. UPS generated US$12.89 billion. For the Canadian National Railway, it was C$4.9 billion.

But there is a profitability problem in passenger transport. Roads are generally paid for with tax dollars and are never expected to pay that money back. Airlines are historically challenging businesses that rarely turn a profit – just look at the wave of bankruptcies in the industry (United Airlines in 2002, Air Canada in 2003, Delta Air Lines in 2005, and American Airlines in 2011, to name just a few).

Passenger rail is no better. Canada’s Via Rail is painfully unprofitable – producing a net operating loss of C$491 million in 2021, C$553 million in 2020, and C$409 million in 2019 before losses could be explained by “covid impacts”. SNCF, widely regarded as one of the best high-speed rail operators in the world, has had 4 profitable years and 5 loss-generating years since 2012. The Shanghai Metro Maglev has never been profitable.

Clearly, there is an issue with passenger transport. No mode of transportation can consistently generate profits. It is critical to find a solution.

TransPod’s Innovative Operating Model

TransPod disrupts the traditional operating model railway operators use. Our approach focuses on maximizing the utilization of the infrastructure rather than only individual train trips.

Conventional railway operators aim to maximize the fullness of each train trip to improve the profit margins of that specific journey. This focuses on the wrong asset. The most expensive asset in any infrastructure project is the infrastructure itself. For example, in TransPod’s project in Alberta, the forecasted capital cost is approximately US$17.9 billion, of which less than $1 billion is for vehicles. Maximizing the utilization of the infrastructure, instead of the individual vehicles, will ensure that the upfront debt can be more quickly paid off, thereby unburdening TransPod from one of the most significant sources of cost for rail operators: ongoing interest payments.

Our approach to maximizing the use of the infrastructure is to offer both cargo and passenger services. This is impossible on maglev trains (maglev is not designed to carry freight) – but we view it as essential. In hours when passenger demand is high, like during your daily commute to and from work, the line will be full of passenger vehicles. In hours when passenger demand is in a lull, cargo shipments will fill the infrastructure. By doing this, TransPod can keep the infrastructure full, smoothing out the revenue throughout the day and making it possible to repay the project debt quickly. Of course, we will still aim to maximize the fullness of each vehicle, but it is not our foremost priority.

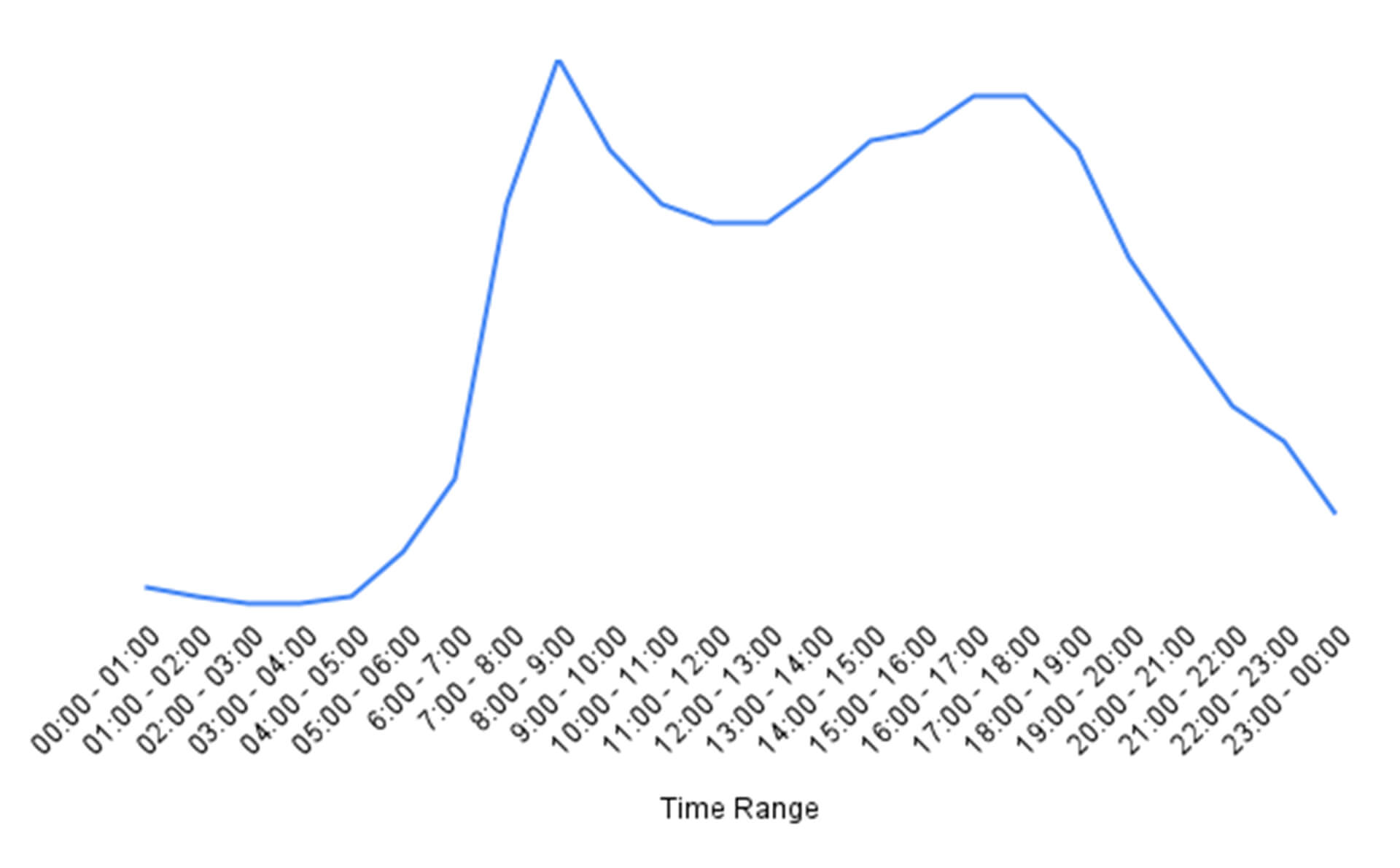

For example, the graph below shows the hour-by-hour daily traffic of a road network in Europe. As you can see, passenger travel is quite uneven; there are sharp peaks from 6-9 am and again from 3-6 pm, a sharp valley in the evening, and a moderate valley at mid-day.

Figure 1: hour-by-hour breakdown of traffic trends on a European road network.

In a passenger-only system, there would only be two options during the “valley” periods: run fewer vehicles, or maintain the same number of vehicles but accept that each one will have fewer passengers. In both cases, the system is less profitable during the valley periods.

In contrast, TransPod will send more cargo vehicles along the line during these low-passenger-demand periods, keeping the line running at near-full capacity throughout all opening hours (6 am to midnight) and therefore driving profitability in a way that passenger-only systems cannot.

Looking at our project in Alberta is a good example which helps clarify which factors are most important. Currently, the TransPod Alberta project is forecast to fully pay back the project debt in just over 20 years. That is largely thanks to our cargo operations; 60% of the “ridership” is expected to come from freight movements, while only 40% is forecasted to come from passenger movements. If TransPod could only carry passengers: the 30-year IRR on the project would drop from 7% to 4%, the project NPV would drop from roughly $50 billion to $30 billion, and the payback period for the debt would be 7 years longer.

Overall, the financial rewards would likely be too low for any private investors to take the risk – the same problem faced today by most high-speed rail and maglev proposals.

Attracting Cargo Partners

Since cargo is essential, TransPod has identified cargo partnerships as a critical aspect of our strategy. We are focused on ensuring our services are well-tailored for two specific types of cargo operators to maximize our cargo demand.

Airports: our stations are designed to be intermodal and highly efficient at transferring cargo between planes, trucks, and the TransPod system. To make this intermodality work, we ensure that each of our corridors has at least one airport connection (i.e. a TransPod station on airport property). This will make it easy for air freight operators to fly cargo into a region and send it quickly to its destination via the TransPod system.

Airports can benefit from allowing a TransPod station on their land: they can leverage the TransPod traffic as an opportunity to turn their site into a cargo or passenger hub (or both), and they can even receive direct revenue from “landing fees” paid by TransPod for the opportunity to land our vehicles on their property. It can be structured as a win-win, as is currently being done in Alberta.

Freight operators: we are designing our system and setting our prices to ensure that the choice to send goods on the TransPod system is evident for freight operators. To that end, we plan to set our prices at a competitive value somewhere between truck and air cargo, which we expect will give us a clear advantage when freight carriers evaluate the speed, cost, and sustainability of each option. (For example, in Alberta, we intend to set prices at approximately 80% of the per tonne-kilometer price of air freight, which is equivalent to approximately 2x the cost of trucking per tonne-kilometer).

Providing a compelling offer for freight operators from a price, speed, and sustainability perspective will enable them to streamline their operations, which currently rely often on “point to point” routes but could be converted into “hub and spoke” routes once the TransPod system is built. For instance, looking again at Alberta, we have spoken with freight carriers who currently fly two small planes into Alberta daily: one to Calgary and one to Edmonton. Once the TransPod system is built, they aim to use either Calgary or Edmonton as their “Alberta Cargo Hub” and fly only one larger plane into the province. Thereafter, any cargo that needs to end up in the other city will be sent there via the TransPod system. In this way, the freight operator will reduce the number of planes they fly each day, helping them avoid unnecessary costs and harmful GHG emissions.

Figure 2: Rendering of a TransPod station

Addressing the Capacity Problem

We often encounter people who question the profitability of our system, criticizing the limitation of our vehicles’ size – which has an initial capacity of 54 passengers or 10 tonnes of cargo. Our capacity is indeed lower than some train systems – for instance, in Alberta, we can carry approximately 4,200 passengers per hour, whereas high-speed trains of a similar distance can usually carry roughly 7,500 per hour or sometimes more. Despite this constraint, there are some important counterpoints to consider.

- We can expand our capacity in the future, with one approach being developing a “virtual coupling” system. This innovative technology TransPod is currently working on will allow multiple vehicles to be dispatched simultaneously in a train-like configuration, connected through a virtual system similar to adaptive autopilot. By implementing this system and dispatching two vehicles together, our capacity immediately increases from 4,200 to 8,400 passengers per hour in Alberta. Furthermore, this technology is scalable, and we can potentially couple even more vehicles together, significantly increasing our capacity beyond current levels.

- Even if we were to cut our capacity by 60% (22 passengers or 4 tonnes per vehicle) – resulting in only 1,700 passengers per hour – our system would still remain marginally profitable. This favorable outcome can be attributed to our system’s relatively low operating costs, compared to high-speed rail, as we require fewer onboard staff and manage maintenance and electricity costs, which are the primary cost drivers. Beyond that, our infrastructure’s simplicity provides an advantage as we can generate propulsion, levitation, and power transmission without needing expensive electromagnets running throughout the infrastructure, as opposed to maglev systems.

- While railways may possess higher capacity, they often struggle to fully leverage it due to various factors. The mere possession of ample capacity is insufficient if the system fails to attract passengers due to its slow speed or expensive tickets.

Overall, TransPod’s innovative operating model challenges the conventional thinking of the transportation industry, demonstrating the importance of prioritizing infrastructure utilization over individual train trips. Likewise, as we continue to innovate, the capacity of our system can grow to match or exceed that of high-speed rail, leading to our main criticism being silenced.

TransPod’s system is designed to be profitable in a way that traditional transportation systems have not been able to achieve. Using innovative technology and an improved operating model, we anticipate that our system will generate strong revenue while providing passengers with fast, safe, and comfortable transportation. As we continue to develop and test our technology, we remain committed to ensuring that our system is profitable and sustainable over the long term – we do not believe it is viable to continue building money-losing systems, as society has for so many decades.

While challenges and risks are certainly associated with building a new transportation system, the potential rewards are worth the effort. TransPod is poised to transform the transportation industry and create a more sustainable future for all, and we look forward to bringing this exciting new mode of transportation to countries worldwide.

We are always open to receiving feedback. We have shared our thoughts on profitability and why we have successfully attracted investors thus far. However, if you hold a different viewpoint, please contact Zach Lamothe via LinkedIn or info@transpod.com and share your perspective. We are eager to learn from other opinions and grow as a company.

Figure 3: Rendering of the TransPod system in Alberta. Note that this rendering is transparent for educational purposes only; the real tubes will be constructed with opaque steel, as shown in the distance in this photo.